The field of robotics has long pushed the innovation envelope, taking humans into increasingly extreme environments such as nuclear zones, space exploration, and deep mining. Working in these extreme environments is often dangerous and to continue to dive into these extreme spaces (both safely and cost-effectively), it is imperative to remove the need for humans to do this dangerous work.

Today, the robotics industry is working towards creating solutions with increased autonomy and developing the ability to work in increasingly unstructured environments. This advancement is largely enabled by integrating AI and machine learning into robotic solutions like we create here at SK Godelius.

Robots developed to work in unstructured environments are relatively new to the market and are starting to be adopted across many industries. We believe the future of robotics relies on advancement in this area and those industry leaders who want to stay ahead of the curve must be aware of the potential of unstructured robotics.

Structured vs. Unstructured Environments

Most of us are familiar with robotics in structured environments — think of common examples such as the robotic arms in manufacturing plans that complete detailed or repetitive tasks or robotic dozing, excavation, and haulage in the mining industry. In that traditional, structured environment, elements within the robot’s work environment are stable, there aren’t many variables, and the robot can reliably execute on its pre-established programming due to this lack of varied environment.

In contrast, in unstructured environments, the work environment may be unpredictable. Unstructured environments contain elements or variables which are unpredictable, and a traditional robot cannot leverage pre-established programming to reliably complete a task.

SK Godelius engineer, Sergio Boccardi explains the difference, “In an assembly line where there is a robot that picks up objects from a conveyor belt, the geometry of the furniture and machinery that is within reach of the robot is known with great precision. Hence, the robot programmer considers these geometries in the robot’s movements. The known geometry is incorporated in such a way that the robot, even if it has certain degrees of freedom, will not collide with the structures surrounding it because they occupy a space that is perfectly known and “mapped” in the program that controls the robot”, says Boccardi.

“Let’s assume now that we need a robot to take the same part as in the previous example, but it may be in a larger area with inclined planes, and there may be other unknown objects. The programming method we used in the previous example would not be functional since the geometry of the environment and objects is not known when programming the robot.

Therefore, we now need a robot that “understands” the environment and can construct a trajectory at runtime to achieve the goal. It radically changes the robot’s programming and the type of sensors we must incorporate so that the robot can “understand” the environment.”

This simple example demonstrates that an unstructured environment is a much more complex challenge for robotics and requires new and innovative ways of thinking and new technologies. That is where robotic autonomy and artificial intelligence comes in.

Autonomy and AI for unstructured environments

Robots operating in unstructured environments was once not possible. But today, by integrating the principles of Artificial intelligence (AI), assisted autonomy and allowing robots to autonomously define strategies to solve complex objectives, robotics are ideal solutions for many industry challenges. “Once you “understand” the environment, the robot must “create” a strategy to reach the goal”, says Boccardi. “Computer-wise, “creativity” can be seen as a process by which the robot builds thousands of simulated solutions that can be applied to the current reality. These solutions must be filtered to rule out those that generate collisions and those that do not reach the objective. Then, the learning process will allow the selection of the “best outcome” based on some optimization criteria.”

However, autonomy is limited to the availability and sophistication of the AI. Boccardi shares, “The level of autonomy in the performance of these robots will depend on the available AI. For example, we can make a robot find a particular piece in a drawer full of parts. We can make the robot learn to take the piece based on its shape and the way it is in the box. However, to take the piece, we must “clear” the environment due to the presence of other objects. This is where the concept of assisted autonomy appears, where a human defines the strategies at various levels, and the robot fulfills each step defined by the human.”

By building on one technological advancement after another, robots will be able to operate in unstructured environments and will increasingly become viable options for industry to increase efficiency and reduce risks.

“Robotics for unstructured environments leads us to develop other disciplines related to AI to provide robots with the ability to solve problems at a higher level. AI allows us to build robots with intelligence comparable to a cockroach, but we still need to compete with chimpanzees.”

– Sergio Boccardi, SK Godelius Engineer

How Godelius is innovating in robotics in unstructured environments

While leveraging AI in robotics for unstructured environments is still a recent advancement, SK Godelius is leading the way in developing robotic solutions for unstructured environments.

In partnership with Vale and NORCAT, SK Godelius is developing a solution for acid train car loading. In acid train care loading, smelter/sulphuric acid (a common chemical by-product of the smelting process) is loaded onto train cars for site removal. Given the risks associated with human exposure to a concentrated acid, it is carefully collected, stored and transported to ensure the health and safety of workers and surrounding communities. The ideal robotic solution would allow workers to stay out of harms way.

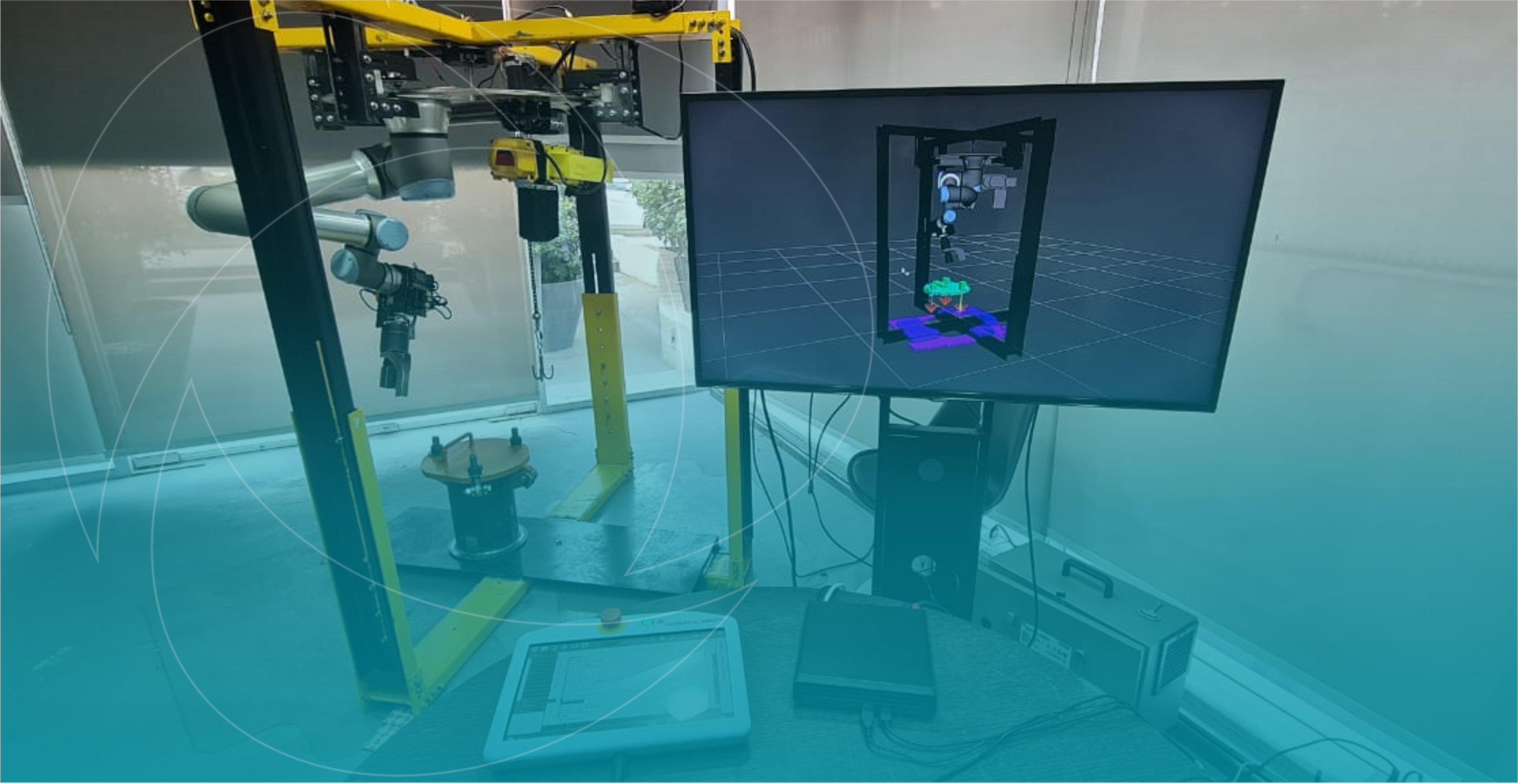

The SK Godelius team integrated AI and semi-autonomous operation technologies to create a solution that is fundamentally new to the industry.

5 innovations in the PoC

- An unstructured scenario is identified due to the variety of wagons and how the robot must approach each one – it is impossible to ensure the spatial location of the components or their shapes in advance.

- A combined topographic-type altimetry system was developed with an artificial vision system based on a stereo-vision camera and the projection of a random pattern.

- A digital twin model is built in real time with the graphic information of the environment and a digital model of the robot’s parts and the other equipment. It represents the environment and the systems involved.

- A trajectory planner was developed that simulates various trajectories in the twin until a feasible and optimal one is achieved.

- The step of inserting the tool into the nut could not be solved by calculating trajectories because it is an unstructured environment. To solve it, we use force-oriented controls, so the robot acts as if it had a sense of touch.

This proof-of-concept project is a launching point for further innovations and applications for acid train care loading that keep workers safe.

Customize an unstructured robotics solution for your business with SK Godelius

Our team is ready to help you solve your robotics challenges. As an industry leader, we conceive, develop, manufacture, integrate, implant, and operate engineering solutions related to automation, teleoperation, robotization and the connectivity of large machines, vehicles, robots and processes in open-pit and underground mining. No matter which environment and operational framework we are at, our priority is to work with you to develop individual projects that bring value to your business.

Contact us to learn more about our process and how we can help your business innovate with robotics in unstructured environments.