2022 has been a year of great technological achievement in the field of robotics. Globally, many advancements have been made in the use of robotics in unstructured environments. Additionally, the integration of technologies based on artificial intelligence makes robotics an increasingly viable solution for a number of challenges across industries.

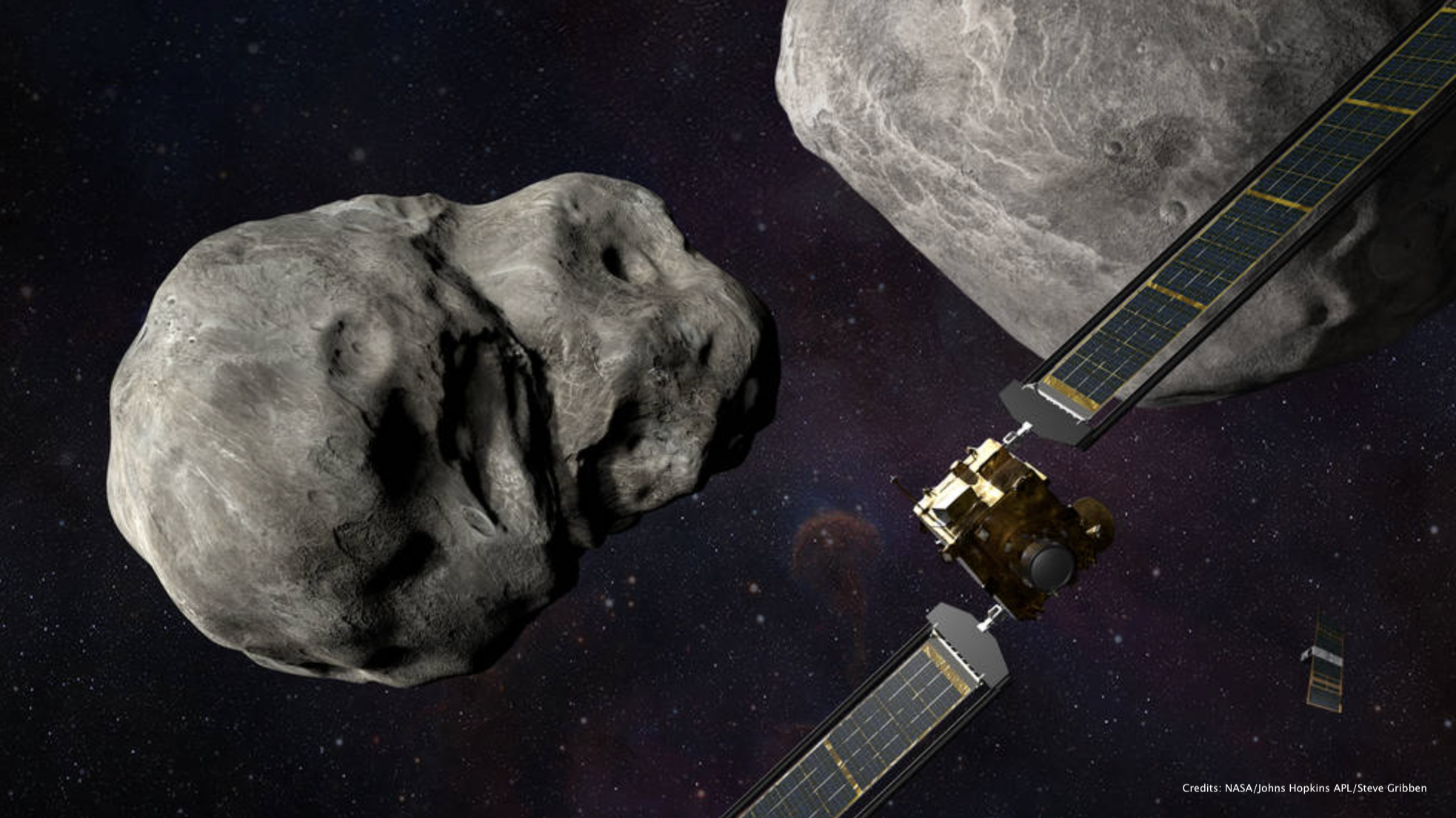

In international news, we see examples of how robots are being used to improve the world around us. Perhaps none more notable than the achievement of NASA’s DART project. NASA made history with DART (or the Double Asteroid Redirection Test) this year by being the first space mission to successfully shift the trajectory of an object in space as part of its planetary defence strategy.

It is actually a binary asteroid system, made up of Didymos, the largest, and Dimorphos, the smallest. Prior to DART’s impact, it took Dimorphos 11 hours and 55 minutes to orbit its larger parent asteroid, Didymos.

On September 26, 2022, DART completed its first successful mission, crashing into the asteroid Dimorphos and altering its speed and orbital path.

As NASA officially confirmed, the data gathered by DART´s investigation team shows “the spacecraft’s kinetic impact with its target asteroid, Dimorphos, successfully altered the asteroid’s orbit. This marks humanity’s first time purposely changing the motion of a celestial object and the first full-scale demonstration of asteroid deflection technology”.

These advancements inspire engineers, including the talented ones here at SK Godelius, to continue pushing the envelope with what robotics can achieve here on Earth and beyond.

Making history in space exploration

DART was launched by NASA to serve a very clear purpose – to protect Earth from potential collisions with near-Earth planetary objects like asteroids and comets. NASA’s mission was designed to assess how much a spacecraft could deflect an asteroid’s trajectory through a controlled collision.

While neither Dimorphos nor Didymos posed a threat to our planet, the mission was a great achievement and proof-of-concept, demonstrating how these strategies can play in defence when integrated with other technological advancements. CEO Fernando Bracco reflects on the impact the DART project has on the industry and how learnings from DART can be applied to solutions here on Earth.

Solving when a significant latency is unavoidable

Latency, or the time span between when an action is initiated vs. when it is completed in another location, is an important practical concern in robotics and in remote operation. “If you imagine that you are operating something at a distance,” says Bracco. “If there is a relevant latency, say a few hundred milliseconds, between when you initiate an action and when it happens, and the operator receives feedback from the robot, there are many, many things that could happen in that time. You have to solve for that, and ideally, you have to give the robot the ability to react with some degree of autonomy.”

In the context of space exploration, a rover, for example, sometimes has a round trip delay between giving instruction and receiving information back from the robot can be hours. In order to ensure safety, engineers send long-complex strings of instructions for the robot to move or execute a very small task so as not to risk damaging or destroying the robot, effectively ending the mission. This means that progress on such missions can be very slow.

“At least for our planet, there are a number of emerging technologies that are helping” says Bracco. “5G and low orbit satellites, for example, promise low latencies and abundant bandwidth that makes a real difference.”

In space, in most cases, you will not be able to change the instructions once they’ve been sent. The robot itself has to react to the environment around it autonomously. “With the right balance between teleoperation and autonomy, we will increase the pace of innovation and our capacity to tackle new challenges,” says Bracco. “Artificial intelligence will give robots more freedom in these scenarios. As time goes on, you will need less human intelligence in the balance, but it will take years, if not decades, to have these things fully autonomous.”

A vision into the future

The success of the DART project is an inspiration and a window into what might be possible in the future with the help of advanced robotics. If we consider the idea of living on another planet, for example, we can see how advanced robotics would be essential. “We should start thinking about ways we can use robotics in those environments, says Bracco. “If you imagine, for example, a lunar base with people living on it. Then imagine the need for food, energy, water – all of those raw materials. It doesn’t sound reasonable to think of sending that from Earth, you could send things occasionally, but eventually, you would need the capability to mine and obtain the resources locally.” “The unstructured/unpredictable character of the robots’ working environment is, of course, also very important. Another fundamental aspect is the need to orchestrate many robots, machines and vehicles that will coexist in the same place at the same time. This involves another layer of development, which must be central to the architecture of the solution sought”.

There is an enormous intersection in how the industry can learn from and ultimately enable something like colonizing another planet with the learnings from robotics today.

“When we consider where to get these raw materials that you don’t have access to on a lunar base, we can take learning from the mining industry here on earth,” says Bracco. “I would say that many of the dexterities needed for many space challenges are being tested now, on Earth in the context of the mining industry. It’s not difficult to imagine translating these capacities to a lunar base or a Martian colony.”

Take inspiration from space exploration and create a robotic solution for your business.

While we may be many years off from populating other planets, SK Godelius is ready to help you solve the challenges of today with robotics. As an industry leader, we conceive, develop, manufacture, integrate, implant, and operate engineering solutions related to automation, teleoperation, robotization and the connectivity of large machines, vehicles, robots and processes in open-pit and underground mining. No matter which environment and operational framework we are at, our priority is to work with you to develop individual projects that bring value to your business.

Contact us to learn more about our process and how we can help your business innovate with robotics.