Codelco is a state-owned Chilean conglomerate, and it is the world’s single biggest copper producer, controlling about 20 percent of total global reserves.

The pumping station Ojos de San Pedro, located in Chuquicamata Division, Chile, consists of 10 wells distributed in the San Pedro River’s hydrographic basin in a mountain range. In the same area is located the Codelco Division so-called Chuquicamata Camp, which houses the team responsible for the operation and maintenance of the equipment required for the extraction and transportation of water. The monitoring of water resources is essential for mining operations since water is fundamental to the extraction process. It is also a scarce resource that must be primarily available for human consumption, especially in a desert environment.

Challenge

- Create a functional solution to monitor the operation of the pumping station Ojos de San Pedro. This area is difficult to access, and it is an extremely relevant station for the mining operation in Chuquicamata Division.

Codelco had defined it as an objective to safely monitor the pumping station, control all the operations, and identify efficiently and quickly possible adjustments. Access to the station was the first challenge of the project due to its geography: high altitude, extreme temperatures and the access roads’ adverse conditions. The journey to Ojos de San Pedro took several hours a day in all-terrain vehicles, which transported the workers, materials, and adequate daily equipment to carry out the tasks that the project demanded.

Solution

Development of two personalized systems to work simultaneously:

- A wireless network platform to monitor variables in the field captured through PLCs.

- A remote control platform with robust high-definition CCTV cameras to work in extreme environments, installed in strategic points.

During the first phase of the project, SK Godelius developed foundations, civil works, lifting of towers and mounting of antennas, installing communications infrastructure, and CCTV outdoor cameras system. It also has created a system of photovoltaic power for all the equipment to provide adequate electrical autonomy. SK Godelius was responsible for executing all the installation, provisioning, commissioning, and delivering training to users.

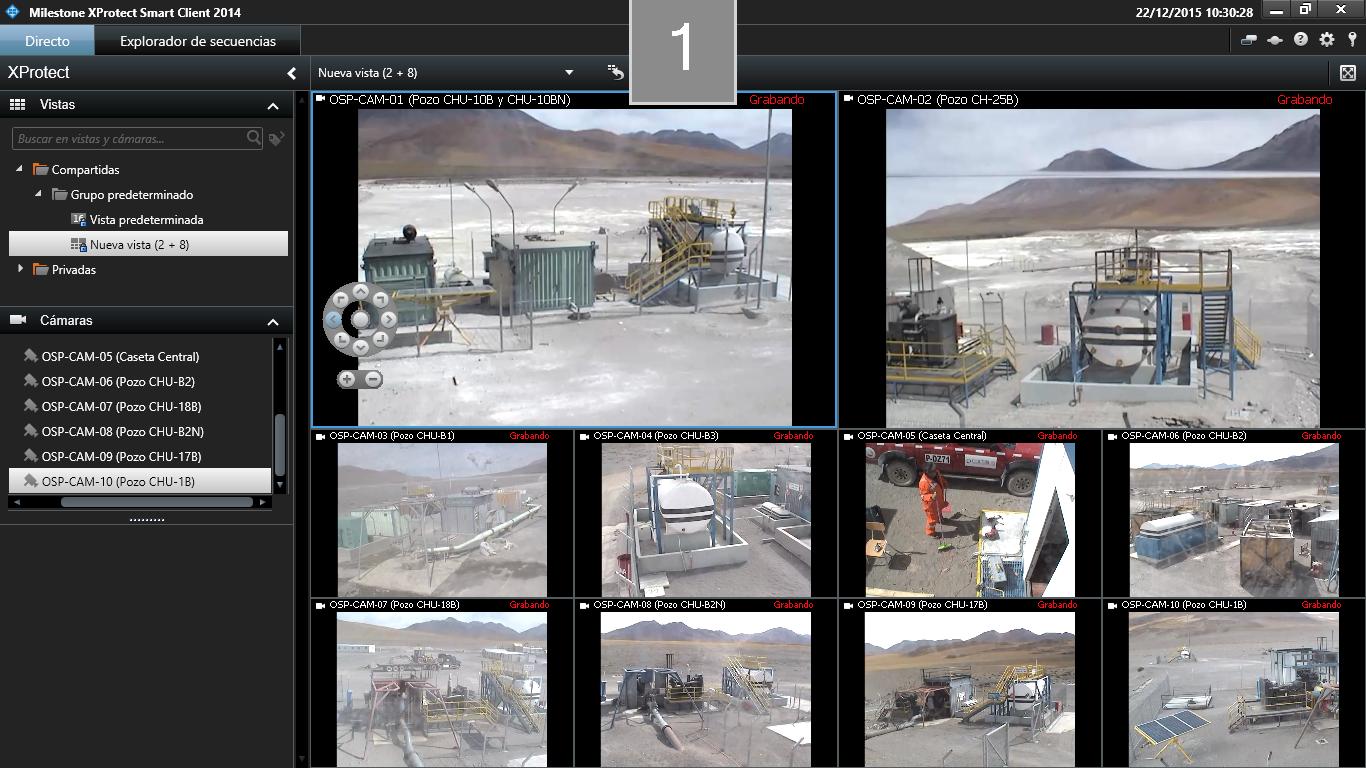

Both systems are work-integrated and are responsible for monitoring different variables in operation. All the images are captured in high definition and sent through a complex wireless transmission network to a monitoring centre at the Chuquicamata site.

The operations centre allows the workers to review the status of all the wells online and act remotely on them according to their operational criteria.

Result

- Both systems favour workers’ safety since they allow remote operations in the field, such as executing diagnosis or performing tasks, so an in-person action is required in the area only if it is strictly necessary.

Even if workers need to execute a task on the site, they will be safer since there are people in the operations centre to guide and protect them. Furthermore, the employees can have online information about each of the wells’ behaviour and status, so it is possible to adapt water flows from the wells efficiently. The project also allows providing crucial data to the regulatory authority.